Mechanical energy storage works in complex systems that use heat, water or air with compressors, turbines, and other machinery, providing robust alternatives to electro-chemical battery storage. The energy industry as well as the U.S. Department of Energy are investing in mechanical energy storage research and development to support on-demand renewable energy that can be stored for several days.

Mechanical energy storage research and development at Southwest Research Institute (SwRI) is helping to develop and commercialize several emerging technologies. Our services span the spectrum of energy storage with expertise in fluids, machinery, chemistry, materials and electrical engineering. Mechanical energy storage integrates with several disciplines, including:

- Hydrogen Energy Research

- Energy Storage Systems

- Thermal Energy Storage

- Thermal, Mechanical and Chemical Energy Storage

Emerging Energy Storage Technologies

Science and engineering services that support development of mechanical storage and other emerging energy storage technologies include:

- Machinery development

- Cycle and system analysis and optimization

- Materials engineering

- Site evaluation and feasibility studies

- Preliminary design

- Systems integration

- Software development

Pumped Heat Energy Storage

Pumped heat energy storage converts electric energy from the grid into thermal energy that is stored as a thermal potential. At full capacity, the system can store energy in tanks for hours or up to several weeks before converting it back to electrical energy. The system can then provide greater than 10 hours of electricity at rated power. The capacity of the system can also be extended by increasing the volume of the storage tanks.

SwRI is currently building a pumped heat energy storage demonstration system with the support of the U.S. Department of Energy, and also has broad expertise in the design, development and operation of supercritical carbon dioxide power systems that are also compatible with energy storage systems.

Pumped Storage Hydropower

Electric power systems use pumped storage hydropower (PSH) for load balancing. The method uses the gravitational potential energy of water, pumped from a lower-elevation to a higher-elevation reservoir using low-cost, off-peak surplus electric power to run the pumps. During periods of high electrical demand, the stored water is returned to the lower reservoir, driving turbines to produce electric power. Although the losses of the pumping process make it a net consumer of energy, the system creates value by providing more electricity during periods of peak demand, when electricity prices are highest.

- Capturing Wind & Saving Sunshine

- FAST Commissioning for Pumped Storage Hydropower (PSH)

- Optimizing West Texas Wind & Solar Energy Generation Using Closed-Loop Pumped Storage Hydropower

Compressed Air Energy Storage

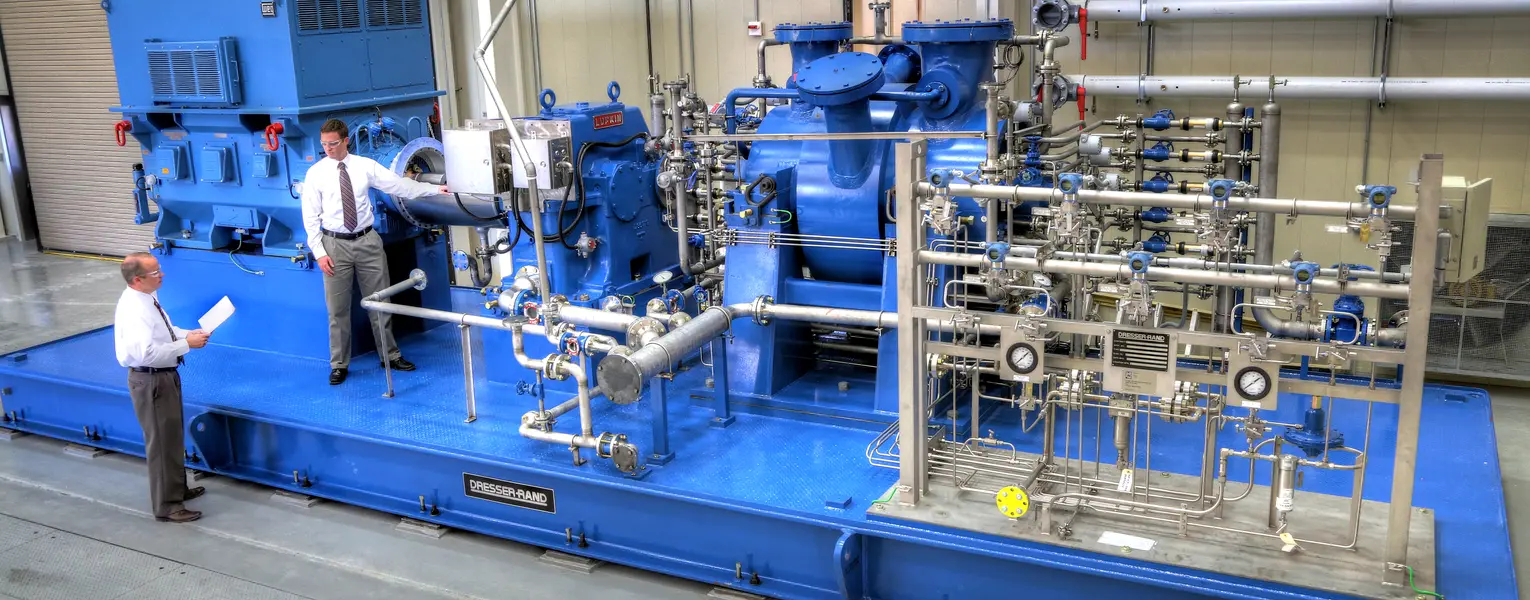

Compressed air energy storage (CAES) plants work similarly to pumped storage hydropower plants, but rather than pumping water between reservoirs, these types of plants compress and store ambient air in an underground cavern during periods of excess power. When power is needed, the air is heated and expanded in a turbine to drive power generation.

SwRI is involved in many different projects advancing CAES technology, including the development of heat exchangers and isothermal compression technology in addition to reciprocating and centrifugal compressor technologies for improving machinery efficiency and range. The Institute is the assignee of a patent for a piston that generates compressed air in a CAES cavern.

Flywheel Energy Storage

Flywheel energy storage systems store energy as kinetic energy in a high-speed rotor connected to a motor or generator, typically in a vacuum environment. The flywheels decelerate in discharge mode and are ideal for short-duration fast-response backup power.

SwRI is involved in projects advancing flywheel component technologies including magnetic bearings, auxiliary bearings and rotordynamic modeling.