The Metallurgical Analysis Laboratory (MET Lab) at Southwest Research Institute provides over 3,700 square feet of space for failure analysis and applied materials characterization, including microstructural assessment and nondestructive evaluation defect verification. The laboratory supports government and commercial clients with efficient and accurate metallurgical analysis of materials used by multiple industries, including aerospace, oil and gas, chemical, manufacturing, transportation, power generation, and biomedical. Notable projects have involved analysis of welded structures, aerospace bearings and gears, high pressure gas turbine components, nuclear power generation components, wire ropes, underground composite fuel storage tanks, and natural gas transmission pipelines.

Metallurgical Testing Services

Our laboratory is equipped with the necessary tools to provide metallurgical testing of many types of materials including metallic, composite, ceramic, polymer, or biomaterial. Laboratory and engineering staff have extensive experience in conducting failure analyses, life assessments of power generation materials and components, crack growth studies, and basic research and testing of metallic and non-metallic materials. Our metallurgical testing services include:

SwRI performs hardness testing for failure analysis and materials characterization.

- Failure Analysis

- Materials Characterization

- Fractography

- Hardness Testing

- Microstructure Evaluation

- Nuclear Material Analysis

- Coating Evaluations

- Defect Verification

- Life Assessments

- On-Site Inspections

- Scanning Electron Microscopy (SEM)

- Energy Dispersive X-Ray Spectroscopy (EDS)

- X-Ray Diffraction (XRD)

Metallurgy Test Standards

- ASTM E18 (Rockwell Hardness Test)

- ASTM E384 (Microindentation Hardness Test)

- ASTM E10 (Brinell Hardness Test)

- ASTM D2240 (Shore Durometer Hardness Test)

- ASTM E112 (Grain Size Measurement)

- ASTM E1382 (Grain Size Measurement)

- DIN EN ISO 643 (Grain Size Measurement)

- GB/T 6394 (Grain Size Measurement)

- DIN EN ISO 945 (Cast Iron Analysis)

- ASTM B 487 (Coating Thickness Measurement)

- DIN EN ISO 1463 (Coating Thickness Measurement)

- ASTM E2109 (Area Percentage Porosity Determination)

Nuclear & Radioactive Infrastructure

SwRI is uniquely qualified to perform metallurgical services, including failure analysis of nuclear plant components and radioactive components. We have a certified hot lab with cells capable of handling multicurie specimens, and a Quality Assurance Plan certified in accordance with 10 CFR Part 50 Appendix B requirements. Visit Radioactive Materials Characterization to learn more.

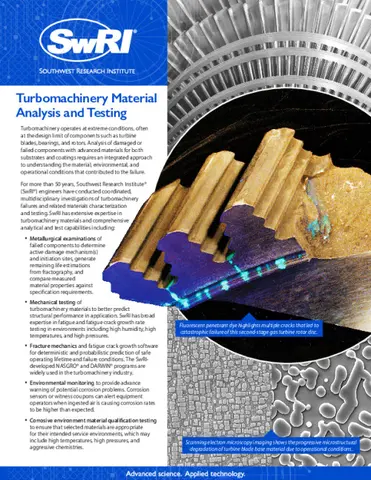

Powerful Scanning Electron Microscope

SwRI’s SEM features energy dispersive X-ray spectrometer to localize analysis and produce clear, sharp images of objects magnified over 1,000,000 times.

Related Services

In addition to fast-turnaround failure analysis and characterization, we support in-depth material research with multidisciplinary expertise in a variety of technical areas, including: